Part Number : TP5100

Function : Single lithium battery charger management chip

Cheap Tool Parts, Buy Quality Tools Directly from China Suppliers:TP5100 charging management power supply module board TP5000 1A 2A compatible with 4.2V 8.4V single and double lithium batteries Enjoy Free Shipping Worldwide! Limited Time Sale Easy Return.

Package : QFN16 Type

- TOPPOWER(Nanjing Extension Microelectronics) TOPPOWER(Nanjing Extension Microelectronics) TP5100 US$0.56 LCSC electronic components online Power Management ICs PMIC - Battery Management leaded datasheet+inventory and pricing.

- Trio Pines Stainless Steel Casters Series TP5100 Load Capacity Per Caster: n/a. FEATURES & BENEFITS: Stainless steel won't rust or corrode under most situations.

Manufactures : Nanjing extension of Microelectronics

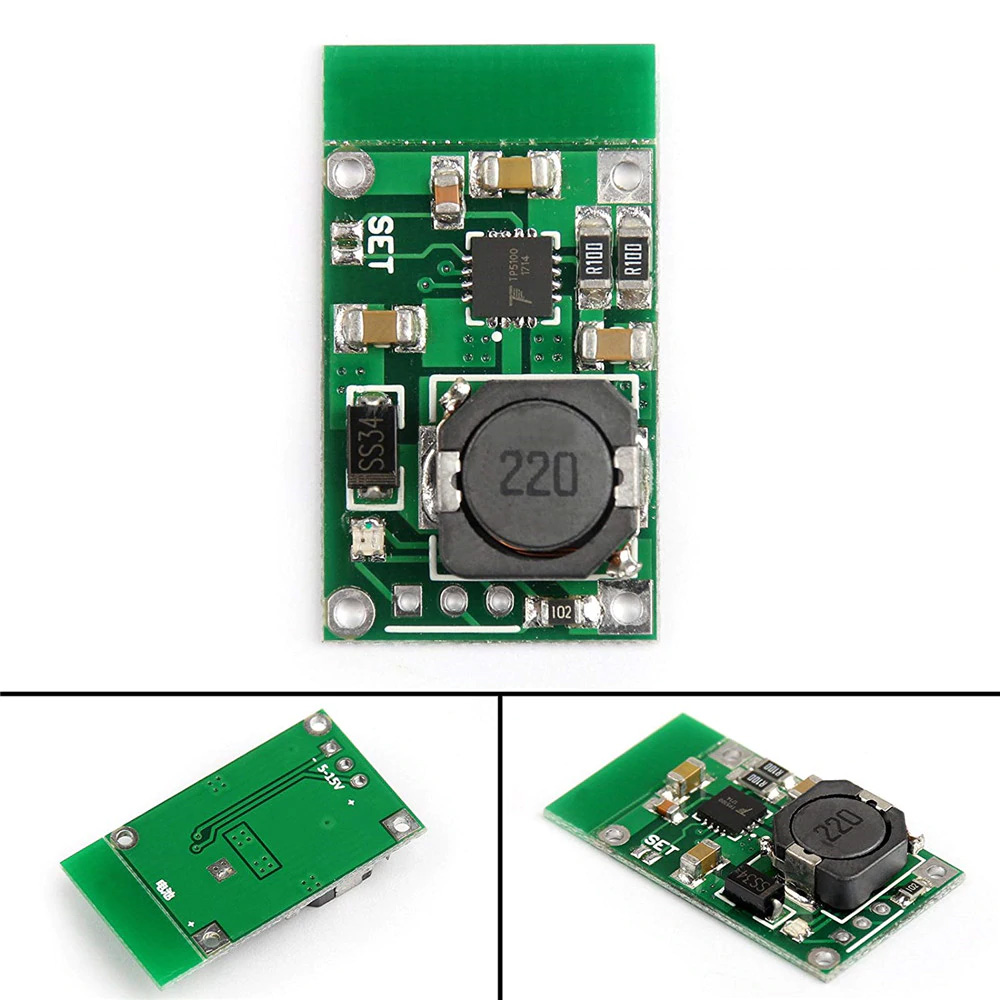

Image

How to find your ip address. Descripiton

TP5100 is a step-down switching double 8.4V / 4.2V single lithium battery charge management chip. QFN16 ultra small package with its simple external circuit, so that the large current charging management application TP5100 ideal for portable devices. Meanwhile, TP5100 built-in input overcurrent, undervoltage protection, over temperature protection, short circuit protection, battery temperature monitoring, reverse battery protection.

Pinout

Features

1. Dual / single 8.4V / 4.2V rechargeable lithium battery

2. Built-in power MOSFET, a switching mode of operation, less heating device, a simple peripheral

3. Programmable charge current, 0.1A – 2A

4. Programmable precharge current, 10% – 100%

5. No external Schottky diode anti-intrusion

6. Wide operating voltage, maximum reach 18V

7. Red and green LED indicates the state of charge

Applications

1. Portable equipment, various chargers

2. Smart phone, PDA, mobile cellular phone

3. MP4, MP5 players, tablet computers

TP5100 Datasheet

Related articles across the web

Posted 13 March 2018

In a recent post, I described my study of the widely available and dirt-cheap TP5100 1/2-cell LiPo battery charger as a possible replacement for my current Adafruit PB1000C-based battery charger. Based on the results of this study, it was clear the TP5100-based system was superior in all respects to my home-brew system:

- Twice the charge current (2A vs 1A) means significantly shortened charge times

- Much smaller and simpler

- Charger current path independent of load path – much lower IR drop

- Battery always connected to the system, so no requirement for ultra-low-drop MOSFET diode

- Much simpler software – no requirement to monitor status of two separate chargers

- No electromechanical relay to screw up.

I constructed a small charger module using some perfboard and a couple of 2-place screw terminals, as shown below (with the previous module shown for size comparison).

New TP5100-based charger module, with previous Adafruit PB1000C-based module below for size comparison. The orange box contains 4 Panasonic 18650 cells. Note the separate charge & load circuits

The following figures show the old and new schematics:

New battery pack schematic

Now that the load current doesn't have to go through the charging module, I was able to replace all main battery wiring with #20 wire for lower IR drops, as shown below

Power wiring replaced with #20 wiring, and 2-pin Deans connectors

#20 wiring to main battery buss. Note in-line safety disconnect

The following figures show the old and new schematics:

New battery pack schematic

Now that the load current doesn't have to go through the charging module, I was able to replace all main battery wiring with #20 wire for lower IR drops, as shown below

Power wiring replaced with #20 wiring, and 2-pin Deans connectors

#20 wiring to main battery buss. Note in-line safety disconnect

The change to the new battery pack also considerably simplified the system hardware and software. The changes to the system schematic are shown below:

Old system schematic. Note the ultra-low-drop MOSFET diode required to keep Arduino Mega alive during charge. and the number of pins required for charge monitoring.

New system schematic. No requirement for diode, as full battery voltage is available at all times. Also, only two pins are required for charge monitoring

Tp5100 Module

The operating system software has also been simplified. Now, instead of monitoring both cell voltages and four different status lines, only two lines have to be monitored. Also, there is now no requirement to correctly sequence the ‘Charger Connect' and ‘Coil Enable signals in order to accomplish correct charging station connect-disconnect behavior. Now the system simply shuts off the motors when the robot connects to the station, and turns them back on again to disconnect. As an added benefit, the six charge status LEDs have been repurposed to show a crude approximation (based on battery voltage only for the moment) of charge status.

Remote pc idrive. RemotePC ensures all remote connections are secured with TLS v 1.2 / AES 256-bit encryption. An additional layer of security is ensured by a unique user-defined Personal Key for each computer. Two-step verification and Trusted devices identification are used to reinforce security during login. Remotely manage your computer with robust reporting tools in near real-time response. IDrive Dashboard makes it easier than ever for IT Managers, Administrators, and families to check on the health of their backups. With the Dashboard you can.

All these changes have caused one minor hiccup in the implementation of the charging station; the new charging voltage is +12V vs +5V as before. As you may recall, the charging station implements a square-wave modulated IR signal, and this signal is produced by a Teensy 3.2 and some associated circuitry, all of which expect +5V. This will require either a dual-output supply, or the addition of an on-board 12-to-5V regulator. This is still up in the air, but I suspect it will land on a simple 3-pin regulator.

Tp5100 Circuit

So far, all the hardware changes (except for the charging station changes) have been accomplished, but the software changes have yet to be implemented and tested. Stay tuned!

Frank